Relyence Process Failure Mode and Effects Analysis (PFMEA) Software

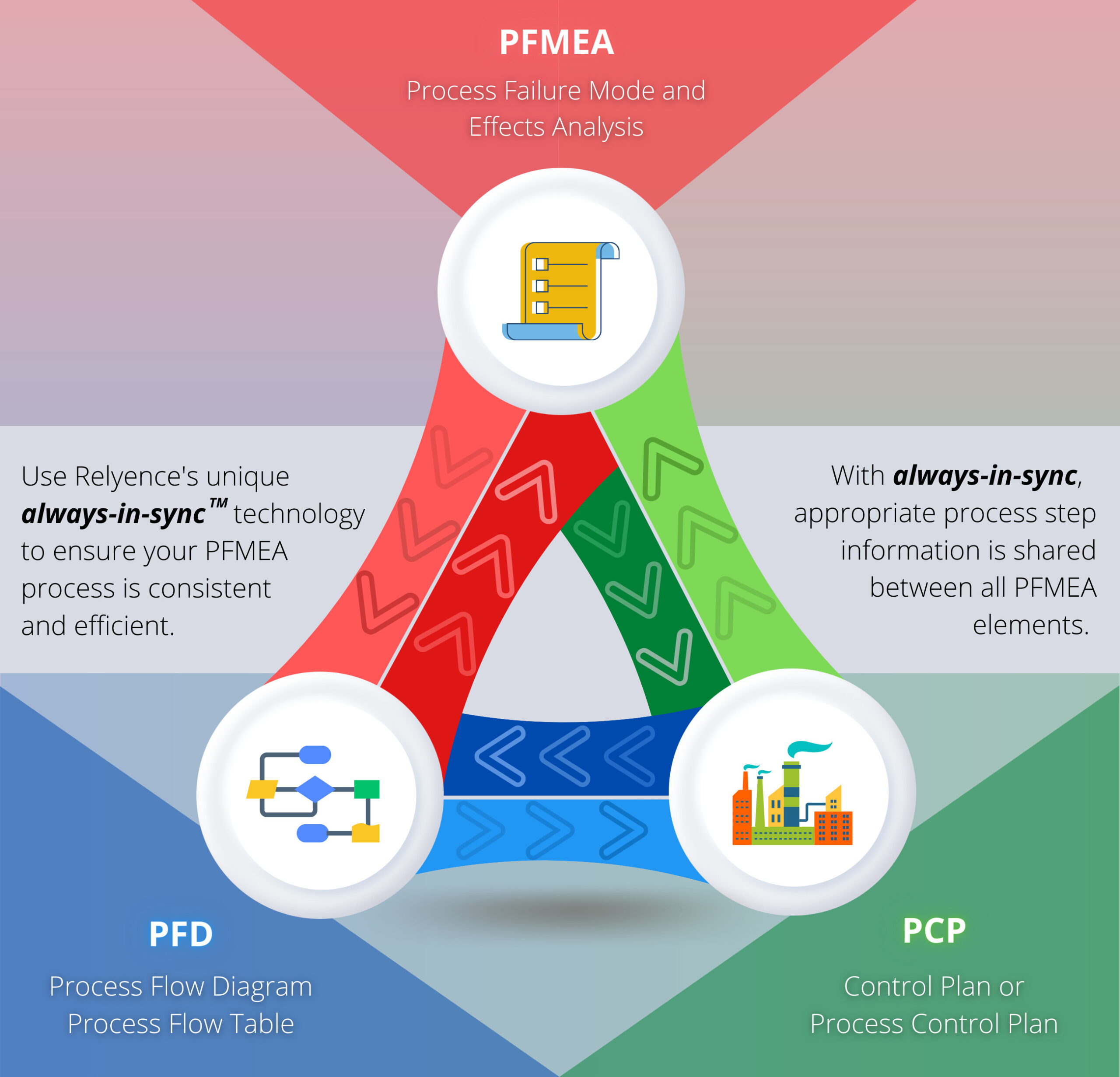

With Relyence FMEA software’s unique always-in-sync technology, you can rest assured that your PFMEAs remain organized and complete. All parts of your process control management – P-Diagram, Process Flow Diagram (PFD), PFMEA Worksheet, and Control Plan (CP or PCP) – are integrated for ease of use and efficiency. Guiding you along in your analysis, Relyence PFMEA ensures that all elements of your failure analysis are accounted for.

Check out our blog post to see always-in-sync in action!

Relyence FMEA: Unique Always-in-Sync Capability Saves You Time Performing PFMEAs

If you perform FMEAs in conjunction with Process Flow Diagrams and Control Plans, you will quickly learn to rely on Relyence FMEA’s unique always-in-sync technology. Keeping your PFMEA information in sync across your PFDs, PFMEA Worksheets, and Control Plans, Relyence PFMEA ensures that your analyses are aligned and organized. Some of the key benefits of this unique Relyence FMEA software feature include:

- Process Steps entered in your Process Flow Diagram (PFD) automatically appear in your FMEA Worksheets and Control Plans.

- Product or Process Characteristics are maintained throughout your analyses.

- Prevention and Detection Controls are carried across your FMEAs and associated Control Plans.

- Your FMEAs are kept in an audit-ready state. The automatic alignment of data across your PFMEAs, PFDs, and PCPs greatly aids in eliminating Non-Conformance Reports (NCRs).

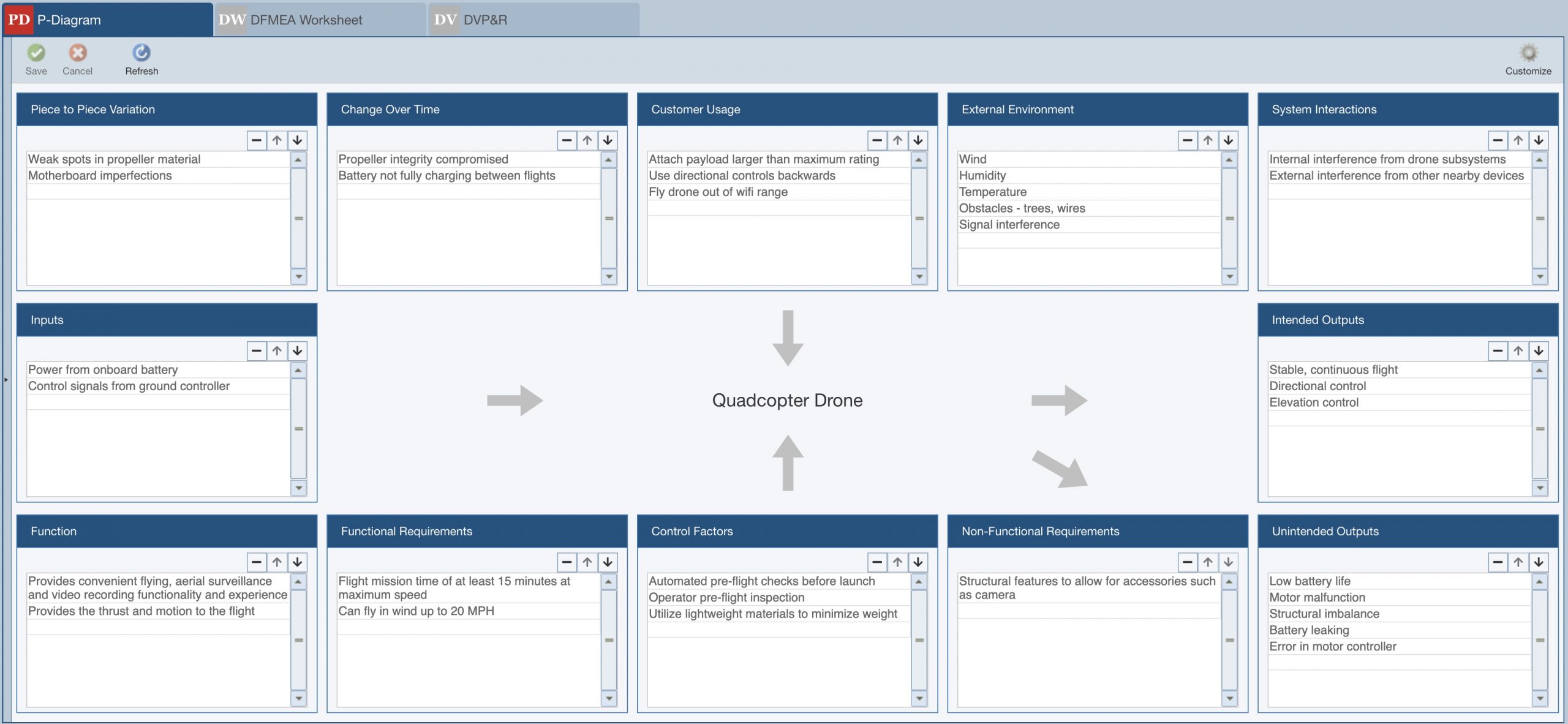

P-Diagram Construction

P-Diagrams (Parameter Diagrams) provide another layer to PFMEAs that can be used for upfront assessment that your required process outputs are met considering all inputs. Relyence P-Diagrams usage is optional, and they can be customized to meet your needs.

Because P-Diagrams provide a compact visual overview, they can aid in understanding the overall process and the interactions of various factors influencing successful operation. Oftentimes, information from the P-Diagram analysis is used as a starting point for the PFMEA Worksheet.

P-Diagrams take into account input signals, output responses, control factors, error states, noise factors, and the interactions between them.

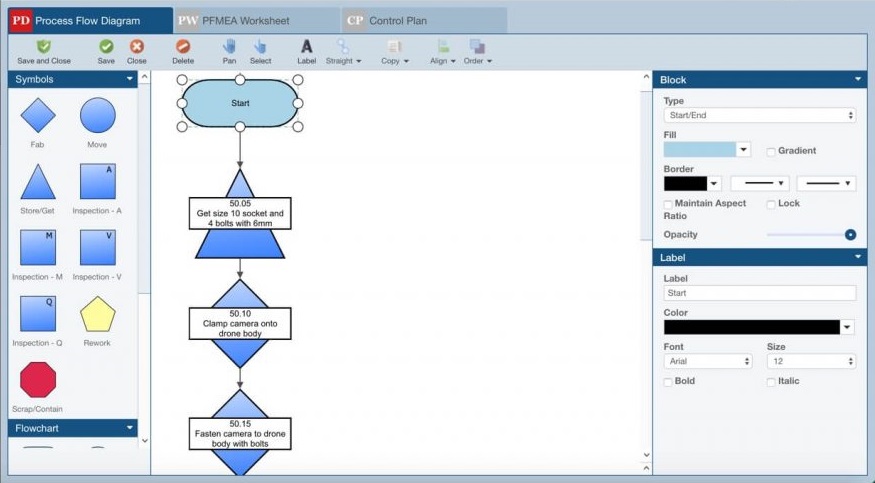

Robust Process Flow Diagram Capabilities

Relyence FMEA supports Process Flow Diagrams with numerous capabilities including:

- Simply drag blocks and drop them in place

- Align and configure your blocks as desired

- Easily assign process related properties

- Create your PFDs in a graphical or a tabular worksheet format

- Quickly toggle between graphical and tabular formats

- Assign visual properties like colors and fonts

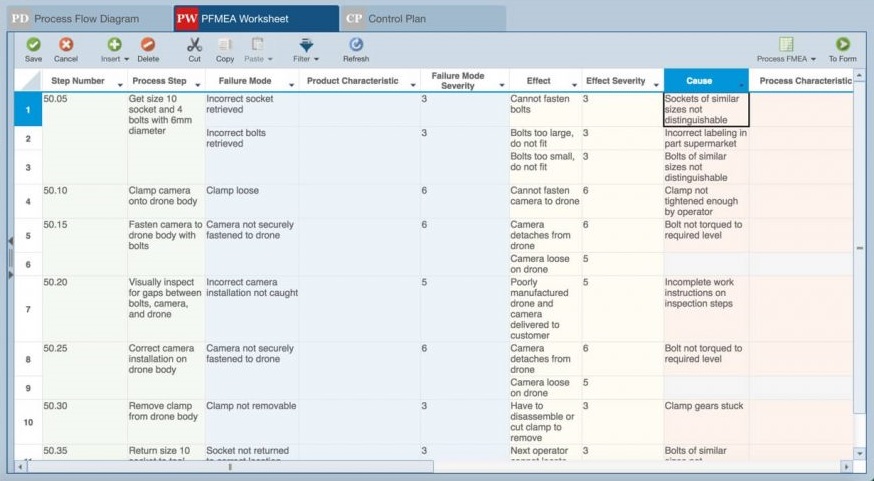

The PFMEA Worksheet: Use Built-in Templates or Customize Your Worksheet

The PFMEA Worksheet is the core of your process analysis. Relyence FMEA offers a standard PFMEA Worksheet with the most commonly used data elements for performing PFMEAs. You can use this template as-is, or modify it as required for your specific needs. Or, you can create a completely custom PFMEA Worksheet if you prefer. Process Steps and related data on your PFMEA Worksheet is automatically kept in sync on your PFD and CP.

Process Control Plans

Relyence FMEA supports Process Control Plans with numerous capabilities including:

- Easily manage all steps of your process

- Effectively control product and process characteristics independently

- Define requirements to evaluate the aspects of your product or process to control

- Document reaction plans to resolve product or process issues

- Create customized views of your data for yourself, a group in your organization, or your entire organization

Benefits of PFMEA Software vs. PFMEA Excel Templates

In many instances, Process FMEAs are performed using an Excel-based approach. While, initially this may suffice, it will quickly become apparent why this is not a good long-term solution. Some of the advantages PFMEA software tools provide are simply not available using Excel:

- PFMEA software establishes a central location for all analyses with easy management. Excel-based analyses are inherently uncontrolled and disconnected due to the multiplicity of documents created.

- When team members are all on a common platform, you are assured that everyone is using the most recent version of data files. Version control is difficult to manage using Excel files: the burden is on team members to coordinate and control varying file versions.

- Using Excel, documents may be inaccessible across different teams and departments due to non-existent ownership control. Most PFMEA software, such as Relyence PFMEA, includes users and groups for roles and permission-based management for efficient control of your PFMEA activities.

Additionally, Relyence PFMEA provides many notable capabilities that are unattainable using Excel:

- Relyence PFMEA software’s innovative always-in-syncTM feature synchronizes data across your Process Flow Diagrams (PFDs), PFMEA Worksheets, and Process Control Plans (PCPs). When facing audits, always-in-sync aids in eliminating one of the most common causes of NCRs (Non-Conformance Reports): data not in alignment across your PFMEA, PFD, and PCP.

- Because many organizations need to complete FMEAs as part of contractual requirements, the fact that Relyence PFMEA software meets several of the most common industry standards — including SAE J1739 and ARP5580, AIAG & VDA, MIL-STD-1629, and Six Sigma — ensures compliancy requirements are met.

- Relyence FMEA’s impressive interface provides a far more comprehensive and intuitive framework for analysis not available using Excel-based FMEA templates.

- Relyence FMEA Knowledge BanksTM have become a must-have feature for today’s FMEA analysts and offer data reusability not possible with a spreadsheet-based approach.

- Relyence-only innovations such as FMEA Data AutoflowTM for automated control of FMEA data relationships and Failure Direct ConnectTM for FMEA-FRACAS integration, advance analyses to an entirely new level simply not possible using Excel.

Read more on the benefits of PFMEA software tools vs. Excel templates.

Give Relyence PFMEA a Test Run!

You can sign up for a completely free, no hassle, no download, no install of Relyence PFMEA! See the benefits of Relyence PFMEA for yourself!

You are also welcome to contact us to discuss your requirements or schedule a free personal webinar to see Relyence PFMEA in action.

Please contact us at any time for questions, concerns, insights, or advice. Our Relyence team has a rich history of knowledge and experience with failure mode and effects analyses. We are happy to help!