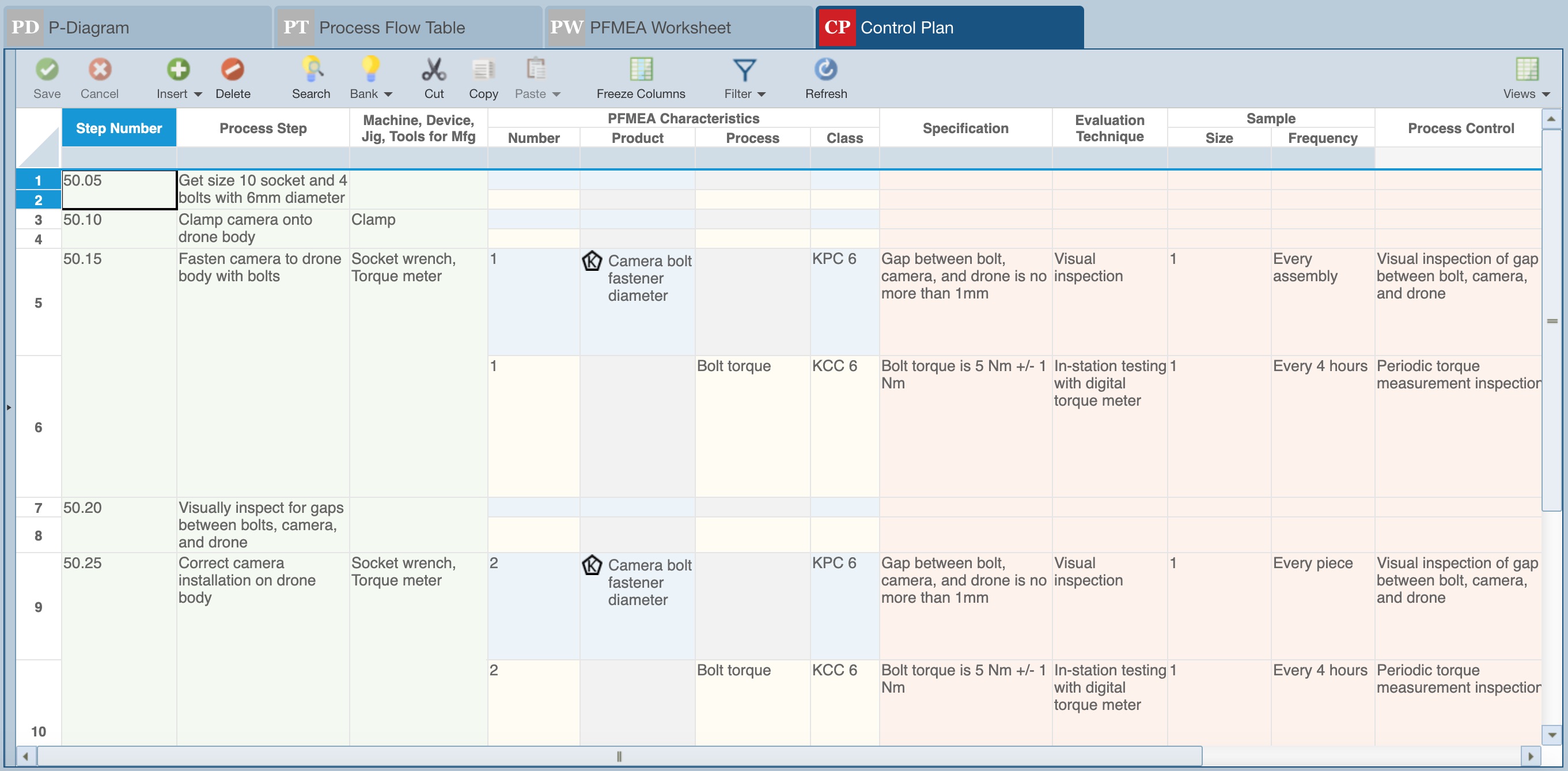

Control Plan (CP)

The final step in your process FMEA work is to create a Control Plan, or CP, if needed. The control plan is used as an organized, detailed plan for documenting all the controls put in place to handle all the failure issues identified in your PFMEA Worksheet as well as product and process characteristics. Ultimately, your CP can be used to create operator instructions.

The process steps are used as the starting point for your CP. Again, remember that your process steps can be entered in either the PFD or PFT, your PFMEA Worksheet, or directly into your CP. Wherever you enter process step numbers and descriptions, they are automatically kept in sync across three of the main elements of your PFMEA. In addition to the process steps, the Product and Process Characteristics you have entered in your PFD and/or PFMEA Product Characteristics you have entered in your PFMEA Worksheet appear in your CP automatically. Any new characteristics you enter in your CP will automatically be added to your PFD/PFT. In the CP, for each Control, enter the specification to be used as the basis for your control, the sample size and frequency, the control method to employ, and the reaction plan to use if the item does not meet specifications.

You can find details regarding how to enter data on the Control Plan in the Entering FMEA Data topic; the same details apply for entering data on the Control Plan.

As with all FMEA Worksheets, the layout can be customized to meet your needs; it can be used as-is, customized as needed, or you can create you own completely custom Control Plan. See Customizing the FMEA Worksheets for details on creating and customizing FMEA Worksheets in Relyence FMEA.